Type II safety helmets are gaining popularity in construction sites and other industries where there is a higher risk of lateral impacts. As safety regulations become more stringent and employers focus more on worker safety, many construction sites are opting for Type II helmets to provide additional protection for their workers. In many cases, Type II helmets are now being required by safety regulations in specific industries or job sites. For example, the Occupational Safety and Health Administration (OSHA) in the United States requires Type II helmets to be worn in situations where workers are at risk of lateral impacts. In addition, many construction companies are choosing to use Type II helmets as part of their safety programs, even when they are not specifically required by regulations. This is because Type II helmets can help reduce the risk of head injuries and improve worker safety on the job. But the question remains, what are type 2 safety helmets? What is the difference between type 1 and type 2, and why is type 2 so popular? In the post, we attempt to address these questions so you can make the decision right for you.

What Are Type 2 Safety Helmets?

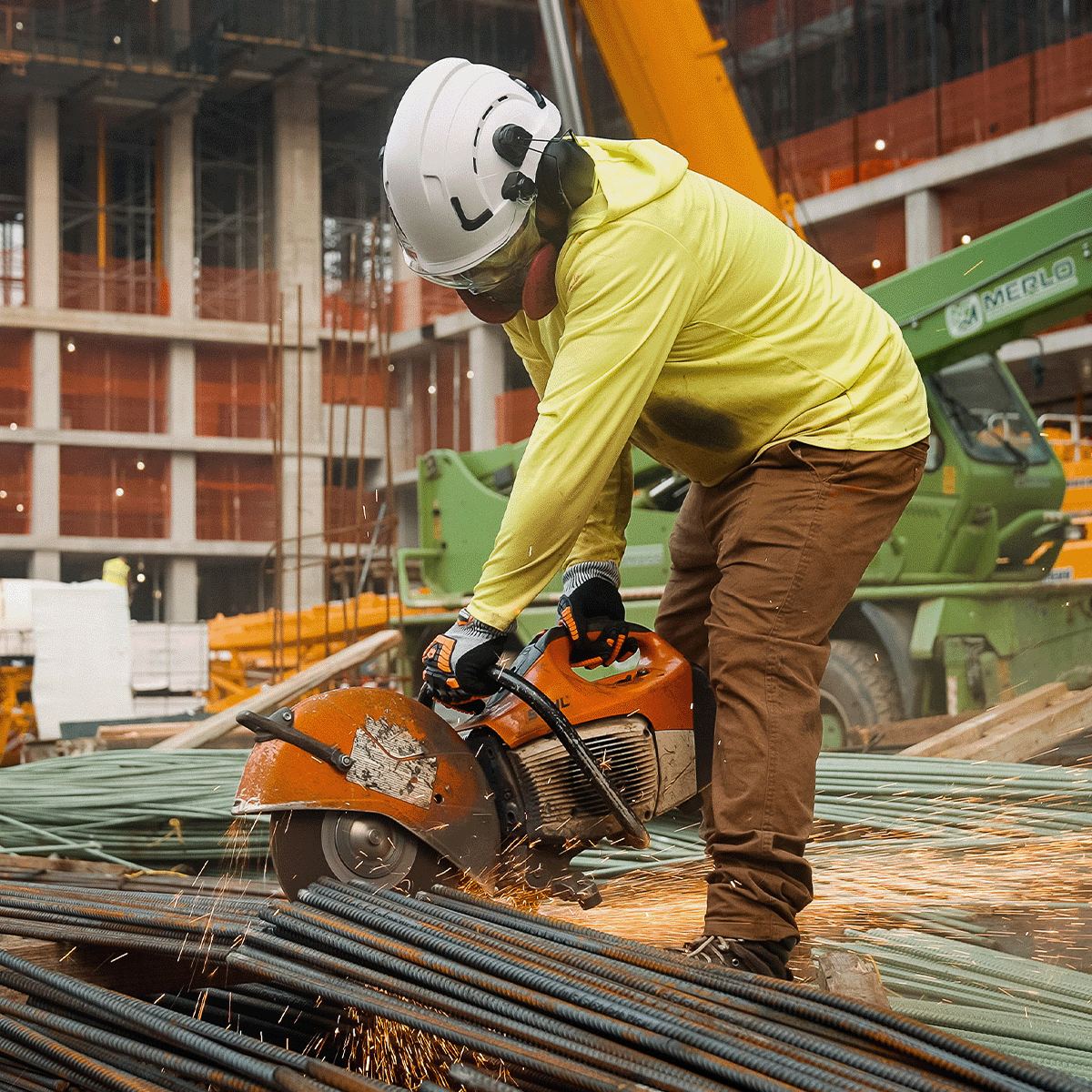

A Type II safety helmet is a type of hard hat that provides protection against impacts to the top and sides of the head. It is designed to provide additional protection to the wearer compared to a Type I safety helmet, which only protects against impacts to the top of the head. Type II safety helmets are commonly used in industries where there is a higher risk of lateral impacts, such as construction sites, industrial manufacturing, and mining operations. They are also typically designed to be more comfortable and provide better ventilation than Type I helmets, since they are intended to be worn for extended periods of time.

What Makes Them Popular?

Type 2 safety helmets have been gaining popularity and becoming the standard on construction job sites due to several factors. We list the most popular ones below: Enhanced protection: Type 2 safety helmets provide both top and lateral impact protection, safeguarding the wearer from falling objects and side impacts. This improved protection is particularly important in construction environments where workers are often exposed to multiple hazards. Regulatory compliance: Many countries and regions have updated their safety regulations and standards to require the use of Type 2 safety helmets on construction job sites. This shift in regulations is a response to the increased awareness of the importance of head protection and the need to reduce workplace injuries. Better design and comfort: Modern Type 2 safety helmets have improved designs that focus on worker comfort, fit, and usability. Features such as adjustable suspension systems, customizable padding, and lightweight materials contribute to increased adoption, as workers are more likely to consistently wear helmets that are comfortable and easy to use. Enhanced visibility: Many Type 2 safety helmets now incorporate high-visibility colors and reflective materials to ensure that workers are easily seen on the job site. This increased visibility can help reduce accidents and injuries, particularly in low-light conditions. Integration with accessories: Type 2 safety helmets often come with built-in attachment points for accessories like face shields, earmuffs, and headlamps. This integration allows for better customization and ensures that workers have the necessary protective gear for their specific tasks.

Type 2 safety helmets have been gaining popularity and becoming the standard on construction job sites due to several factors. We list the most popular ones below: Enhanced protection: Type 2 safety helmets provide both top and lateral impact protection, safeguarding the wearer from falling objects and side impacts. This improved protection is particularly important in construction environments where workers are often exposed to multiple hazards. Regulatory compliance: Many countries and regions have updated their safety regulations and standards to require the use of Type 2 safety helmets on construction job sites. This shift in regulations is a response to the increased awareness of the importance of head protection and the need to reduce workplace injuries. Better design and comfort: Modern Type 2 safety helmets have improved designs that focus on worker comfort, fit, and usability. Features such as adjustable suspension systems, customizable padding, and lightweight materials contribute to increased adoption, as workers are more likely to consistently wear helmets that are comfortable and easy to use. Enhanced visibility: Many Type 2 safety helmets now incorporate high-visibility colors and reflective materials to ensure that workers are easily seen on the job site. This increased visibility can help reduce accidents and injuries, particularly in low-light conditions. Integration with accessories: Type 2 safety helmets often come with built-in attachment points for accessories like face shields, earmuffs, and headlamps. This integration allows for better customization and ensures that workers have the necessary protective gear for their specific tasks.

Difference Between Type 1 & 2 Helmets

The main difference between a Type 1 and Type 2 safety helmet is the level of protection they offer against impact. As mentioned previously, the Type 1 helmet is designed to provide protection to the top of the head only. They are commonly used in industries where there is a lower risk of lateral impacts, such as forestry or engineering. Type 2 helmets, on the other hand, are designed to provide additional protection against impacts to the top and sides of the head. They are commonly used in industries where there is a higher risk of lateral impacts, such as construction, mining, or manufacturing. Another difference between Type 1 and Type 2 helmets is the level of electrical insulation they provide. Type 1 helmets are generally designed to provide protection against low-voltage electrical hazards, while Type 2 helmets offer higher levels of protection against high-voltage electrical hazards.

The main difference between a Type 1 and Type 2 safety helmet is the level of protection they offer against impact. As mentioned previously, the Type 1 helmet is designed to provide protection to the top of the head only. They are commonly used in industries where there is a lower risk of lateral impacts, such as forestry or engineering. Type 2 helmets, on the other hand, are designed to provide additional protection against impacts to the top and sides of the head. They are commonly used in industries where there is a higher risk of lateral impacts, such as construction, mining, or manufacturing. Another difference between Type 1 and Type 2 helmets is the level of electrical insulation they provide. Type 1 helmets are generally designed to provide protection against low-voltage electrical hazards, while Type 2 helmets offer higher levels of protection against high-voltage electrical hazards.

Why Type 2 Helmets Are a Step in the Right Direction in Improving Worker’s Safety?

A Type II safety helmet is a step in the right direction in improving worker safety because it provides additional protection against impacts to the sides of the head, which is an area that is often at higher risk of injury in many industries. By providing this additional level of protection, a Type II helmet can help reduce the risk of serious head injuries in the workplace. In industries where there is a higher risk of lateral impacts, such as construction or mining, a Type II helmet can help protect workers from a variety of hazards, such as falling objects, collisions, or impacts from machinery. This can help reduce the number and severity of head injuries on the job, which can improve worker safety and productivity. Additionally, Type II helmets are often designed to be more comfortable and provide better ventilation than Type I helmets, which can help encourage workers to wear them for longer periods of time. This can help improve compliance with safety regulations and reduce the risk of injuries caused by workers not wearing their helmets. Defender Safety recently launched the H2 series Safety helmets that offer Type 2 protection. It comes in 7 different colors and two classes: Class E and Class C. The type C helmet has 360 degrees of ventilation and is great when working on hot summer days. The Type E helmet utilizes the patented Volfense™ technology to protect users against 20,000 Volts. Regardless of the class, the H2 is the perfect solution for the job site, or if you are involved in any environment that requires head protection like mining and forestry. The Defender Safety H2 is OSHA compliant and exceeds all the ANSI Z89 and EN 12492 testing requirements so your workers can feel confident about the task at hand. Interested in learning more about the product? Click the “Shop now” button below!

A Type II safety helmet is a step in the right direction in improving worker safety because it provides additional protection against impacts to the sides of the head, which is an area that is often at higher risk of injury in many industries. By providing this additional level of protection, a Type II helmet can help reduce the risk of serious head injuries in the workplace. In industries where there is a higher risk of lateral impacts, such as construction or mining, a Type II helmet can help protect workers from a variety of hazards, such as falling objects, collisions, or impacts from machinery. This can help reduce the number and severity of head injuries on the job, which can improve worker safety and productivity. Additionally, Type II helmets are often designed to be more comfortable and provide better ventilation than Type I helmets, which can help encourage workers to wear them for longer periods of time. This can help improve compliance with safety regulations and reduce the risk of injuries caused by workers not wearing their helmets. Defender Safety recently launched the H2 series Safety helmets that offer Type 2 protection. It comes in 7 different colors and two classes: Class E and Class C. The type C helmet has 360 degrees of ventilation and is great when working on hot summer days. The Type E helmet utilizes the patented Volfense™ technology to protect users against 20,000 Volts. Regardless of the class, the H2 is the perfect solution for the job site, or if you are involved in any environment that requires head protection like mining and forestry. The Defender Safety H2 is OSHA compliant and exceeds all the ANSI Z89 and EN 12492 testing requirements so your workers can feel confident about the task at hand. Interested in learning more about the product? Click the “Shop now” button below!